|

|

Hey guys I know everybody out there has over the years made some of their own tools. Some people make their own because they simply cannot buy what they need or sometimes you can make some things better than the originals. Can people who have made their own tools share photos with people on this site so we can marvel at your work and as a bonus maybe make our own too!!!!

Reply:Here are a couple of "heavy duty" hammers I made years ago. They are turned from old cold chisels that I annealed and then tempered after they were finished. I cut down small machinest hammer handles to fit them.

Reply:Do you use those when you're forming some of your brass work?"Any day above ground is a good day"

http://www.farmersamm.com/

Reply:I used the one on the bottom to drive those 35 brass pegs in that last knife I built.I use both of them working on guns and various other things. I used to build muzzle loading rifles and did some brass wire inlay. I built the top one specifically for that but have found a lot of other uses for it.

Reply:The machining is great.I've made some "tools", more like fixtures I guess, for doing rear ends. They look pretty primitive.Post them tomorrow so y'all can get a good laugh

"Any day above ground is a good day"

http://www.farmersamm.com/

Reply:You didn't say they had to be as pretty as Oldtimers'...TH350/400/700R4 transmission clutch piston compression tools and pump alignment band.

Cummins 855 accessory drive pulley installer. Works w/o pulling radiator. Approximately 15 years old which explains the ugly nubie mig welds. 'First' attempt was too short hence the add-on.

Chevy oil pump primer. Who doesn't have one of these? This one's probably close to 30 years old and primed a bunch of alcohol sprint car motors among a number of grocery getters.

MM200 w/Spoolmatic 1Syncrowave 180SDBobcat 225G Plus - LP/NGMUTT Suitcase WirefeederWC-1S/Spoolmatic 1HF-251D-1PakMaster 100XL '68 Red Face Code #6633 projectStar Jet 21-110

Save Second Base!

Reply:After lookin' at all of this, I might just leave my stuff in the shed. Specially since I gotta go dig thru the scrap pile to find a carrier, and cut the weeds down in front of the pumpkin on the "new" Chev.Geesh

"Any day above ground is a good day"

http://www.farmersamm.com/

Reply:And then theres...Fuller dual disc clutch alignment tool. Got some 'bought' versions too.

GM 90 degree V-6 mechanical fuel pump push rod block bore fixture. Used to modify non-mechanical fuel pump block for mechanical fuel pump use (i.e. marine application or if you just don't want to use an electric unit).

Can't for the life of me remember what the heck this was for!

MM200 w/Spoolmatic 1Syncrowave 180SDBobcat 225G Plus - LP/NGMUTT Suitcase WirefeederWC-1S/Spoolmatic 1HF-251D-1PakMaster 100XL '68 Red Face Code #6633 projectStar Jet 21-110

Save Second Base!

Reply:

Originally Posted by farmersamm

After lookin' at all of this, I might just leave my stuff in the shed. Specially since I gotta go dig thru the scrap pile to find a carrier, and cut the weeds down in front of the pumpkin on the "new" Chev.Geesh

Reply:Duane, that last one looks like it's for a spindle nut on a 4WD front axle. Just my guess, MikeOl' Stonebreaker "Experience is the name everyone gives to their mistakes"Hobart G-213 portableMiller 175 migMiller thunderbolt ac/dc stick Victor O/A setupMakita chop saw

Reply:

Originally Posted by mla2ofus

Duane, that last one looks like it's for a spindle nut on a 4WD front axle. Just my guess, Mike

Reply:Don't encourage the guy, he'll drag 'em all out

Damn Duane. Now I know for sure, my stuff's stayin' outta sight!!!!

"Any day above ground is a good day"

http://www.farmersamm.com/

Reply:Engine casing separator (Suzuki TL1000)

Fork spring compressor

Bikelift

Reply:

Originally Posted by farmersamm

Don't encourage the guy, he'll drag 'em all out

Damn Duane. Now I know for sure, my stuff's stayin' outta sight!!!!

Reply:Thats the kinda stufff im talking about awesome guys!!! Especially the Sprintcar engine stuff!!!

Reply:Yeah but ElGuapo has to go and show off by paintin' his stuff.

ElGuapo,Is that a thrust bearing under the nut on the fork compressor? Nice lift.

MM200 w/Spoolmatic 1Syncrowave 180SDBobcat 225G Plus - LP/NGMUTT Suitcase WirefeederWC-1S/Spoolmatic 1HF-251D-1PakMaster 100XL '68 Red Face Code #6633 projectStar Jet 21-110

Save Second Base!

Reply:Yep, that's a thrust ball bearing. I must admit

i bought a new one for that. Gives you more feel what's going on in the compressor. Battery drill makes it a fast fork compressor

At least the fork tube clamp is a recycled bent clipon.Painting the stuff keeps the rust flakes off my shiny clean and oily bike bits. They're leftovers (Kawasaki green and Suzuki katana metallic blue).

Reply:Fixture for holding 10 1/2 Chevy carrier while torqueing ring gear boltsNot very hi tec

Attached Images

"Any day above ground is a good day"

http://www.farmersamm.com/

Reply:Here's the press I made a couple of weeks ago and I made a set of the roller stands that are to the right in the pic.

DewayneDixieland Welding

MM350PLincoln 100Some torchesOther misc. tools

Reply:

Originally Posted by farmersamm

Fixture for holding 10 1/2 Chevy carrier while torqueing ring gear boltsNot very hi tec

Reply:

Originally Posted by littlefuzz

Here's the press I made a couple of weeks ago and I made a set of the roller stands that are to the right in the pic.

Reply:

Originally Posted by duaneb55

Doesn't have to be hi tech - just functional and get the job done which that does.

Reply:I've made a few things:A knife with differential heat treatment:

Attached Images

Reply:Also a Treadle hammer

Attached Images

Reply:A Hydraulic Press with a treadle pedal to operate, leaving hands free to work:

Attached Images

Originally Posted by Bob Warner

I've made a few things:A knife with differential heat treatment:

Reply:duaneb55I would bet anyone here, with a little reading could make a knife that is great. Heat treat is the key.The treadle is large to accommodate right or left handed people. I have a lot of visitors to my shop.The bed is not adjustable on the press. The press was made as a dedicated tool for making damascus steel for knives. The welding process is a lot faster with a press than an anvil and hammer.There are pictures of my damascus railroad spike knife in another thread.Unfortunately I need to rebuild the press, I sold it (and a bunch of other stuff) after a motorcycle accident to pay the bills, I really miss it.

Reply:Lets see, I have made pullers, specialty sockets, punches, all kinds of stuff. My favorite was the day I cut a torch tip in 1/2 to make a "boiler tube tip" to get in to a tght spot, everyone thought I was crazy when I went to the chop saw with the torch, till it worked

. All the tools I have made have saved me countless $$$ off the tool trucks and many hours of doing it the hard way.Disclaimer; "I am just an a$$hole welder, don't take it personally

."

Reply:

Originally Posted by Bob Warner

duaneb55I would bet anyone here, with a little reading could make a knife that is great. Heat treat is the key.The treadle is large to accommodate right or left handed people. I have a lot of visitors to my shop.The bed is not adjustable on the press. The press was made as a dedicated tool for making damascus steel for knives. The welding process is a lot faster with a press than an anvil and hammer.There are pictures of my damascus railroad spike knife in another thread.Unfortunately I need to rebuild the press, I sold it (and a bunch of other stuff) after a motorcycle accident to pay the bills, I really miss it.

Reply:Bob, you are GOOD.I was digging through the tool boxes today looking for an air chipper and found several tools I have made that I had forgotten about. I've even forgotten what a couple of them were made to do. A couple made for a one time use were so crude I couldn' believe I made them.

I won't bore you with pictures though.

Reply:

Originally Posted by duaneb55

Nice job on the press Dewayne. I take it you can slip a larger capacity jack in there if needed too?

Reply:The press is built as well, if not better, than my 20 ton commercially bought press.Paint would do marvels

Ever been to an estate auction on a farm? If it's not painted, it's called "shop built". Bidders walk away with it for nothin'.Slap a coat of paint on it, and all of a sudden it's gold

"Any day above ground is a good day"

http://www.farmersamm.com/

Reply:duane,Damascus is basically steel folded and welded many times and it creates a pattern. In my case it is not TRUE damascus but it is universally called damascus. What I do and the other knifemakers nowdays make what is called "Pattern Welded steel" and consists of alternate layers of two or three different steels. After welding and manipulating it you make your knife and then etch in ferric chloride to bring out the pattern.for those that may not have seen the knife duane and I are talking about, here it is:

Here is a gate and my headache rack:

Oldtimer,I am sure that anyone here could make what I have but thanks for the compliment.And remember:

Attached Images

Last edited by Bob Warner; 11-16-2008 at 08:34 PM.

Reply:thats phenomenal. when i get some good pics of the rear wheel runout indicator, stepped axle tool and valve spring compressor adapter (for use on shim-under-bucjet bike motors) i'll post up.. all my pics are garbage.

Last edited by whitehendrix!; 11-20-2008 at 01:10 AM.http://kawispeed.com/ -moderator and tech deluxewww.myspace.com/trickortrack -cuz i have no life

Reply:needed to bend rebar for a job didnt want to spend $39.00 for a bender

Attached Images

Reply:I don't know if this will work:link - - http://weldingweb.com/vbb/showthread.php?t=25448A butterfly without wings, is just an ugly bug

Reply:Jig for tiging band saw bladesWire, spring or small rod benderpilot brg puller

Attached Images

A butterfly without wings, is just an ugly bug

Reply:[QUOTE=Bob Warner;227395]duane,Damascus is basically steel folded and welded many times and it creates a pattern. In my case it is not TRUE damascus but it is universally called damascus. What I do and the other knifemakers nowdays make what is called "Pattern Welded steel" and consists of alternate layers of two or three different steels. After welding and manipulating it you make your knife and then etch in ferric chloride to bring out the pattern.for those that may not have seen the knife duane and I are talking about, here it is:How long does it take to make one, and how many folds?A butterfly without wings, is just an ugly bug

Reply:You guys have posted some very creative solutions.

Sometimes the answer is just the same old tool, but used more creatively.For example, I needed to pull this apart, but with the limited cheap tools that were available at the job:Attachment 25414The Crescent wrench became a Crescent-puller. The 3/4 wrench became a chain de-railer. But I was still lacking a hammer...That's when I was offered a local specialty tool - a "Cammer."Attachment 25415Ergonomic handle, and a nice hard strike face too! I guess they have two popular lengths - six and eight.

Last edited by denrep; 10-19-2010 at 11:37 PM.

Reply:hers some stuff i made for my bike shop.. mostly made when i was a machinist, being that the allen drives you see are courtesy of lunch break time at the company.they're 302 stainless.the gold claw lookin thing is 6061-T6511. i milled it using a CNC (in manual mode) with a 2 flute mill .500 endmill and a keyseat cutter. i needed it to be perfect, thus why i didn't do it on the bridgeport like the axle tools. runout and angular misalignment between the mating face and pointer (.250 stainless rod) is a few thousands IF that.. i got it pretty much in the ten thousandth.the valve tool adapter is just some 1/2" conduit (emt) that i nitched and welded washers to. i REFUSE to pay several hundred bucks for something i can make. you guys are the fisrt to see my creation!! i should patent.. lol

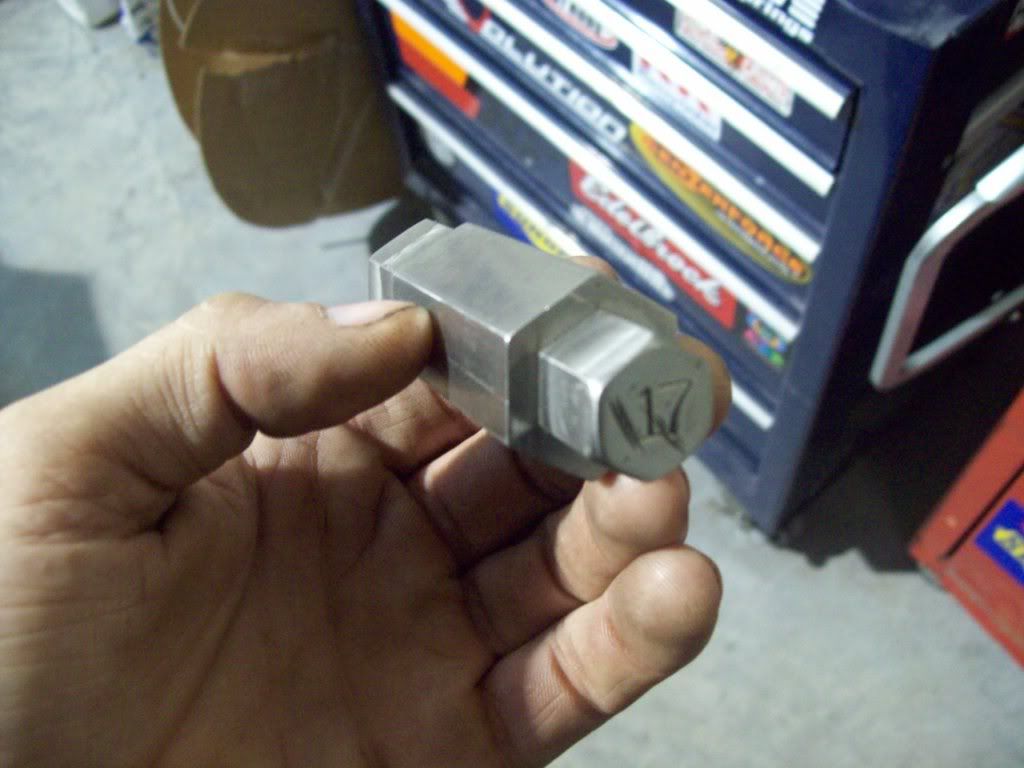

axle tool. mainly for use on kawi crotch rockets like mine in my avatar. 17 and 21MM i've made 18, 19, 20 and 22MM ones as well out of 1" stainless hex bar

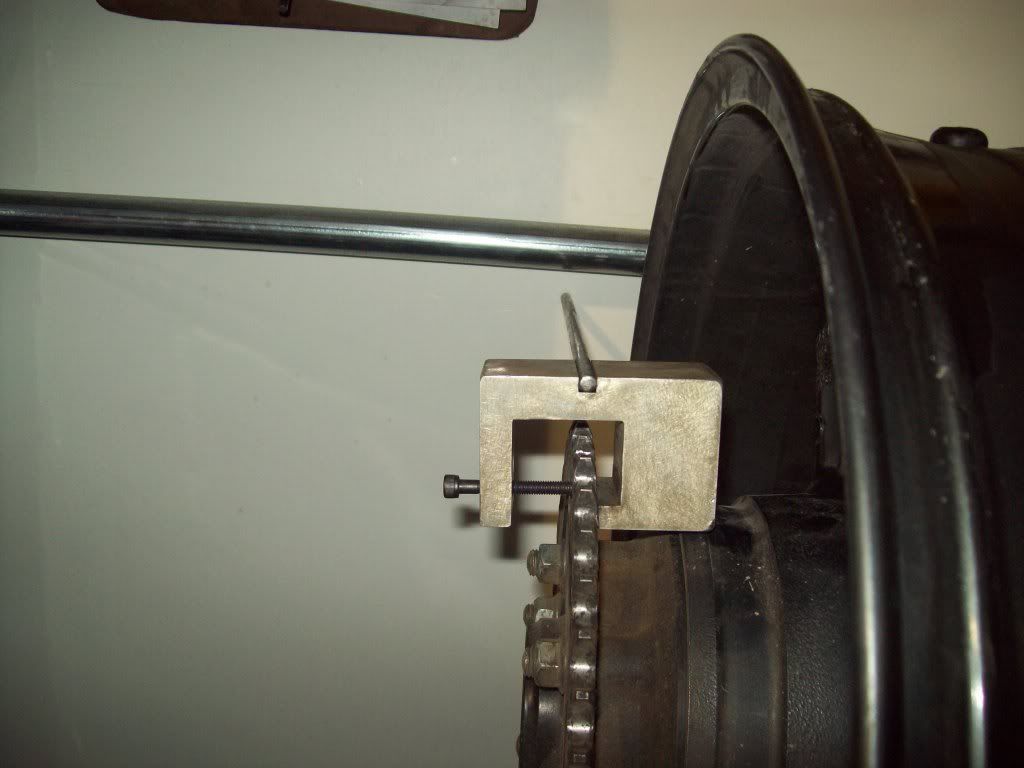

my fav tool .. it looks like it's got a bow, but i assure you it's straight!! hah.. i shellmilled it square before AND after milling the pocket.

basically, the poiter HAS to fall in between the chain's sideplates and point right at the drive sprocket.. if not, this will indicate which way the wheel is out.. it'll work on any spocket it seems (so far).. 5 series and 6 series chain (5/8 and 3/4 pitch) and 520-530 width ( 520-.252 roller width, 525-.313, 530-.375) chains all comply.valve compressor adapter. (ugly as hell, but very functional)

http://kawispeed.com/ -moderator and tech deluxewww.myspace.com/trickortrack -cuz i have no life

Reply:your typical $20. sear automotive valve compressor (impossible to use with bikes)

now, a shim-under-bucket valve removing BEAST!!! haha!

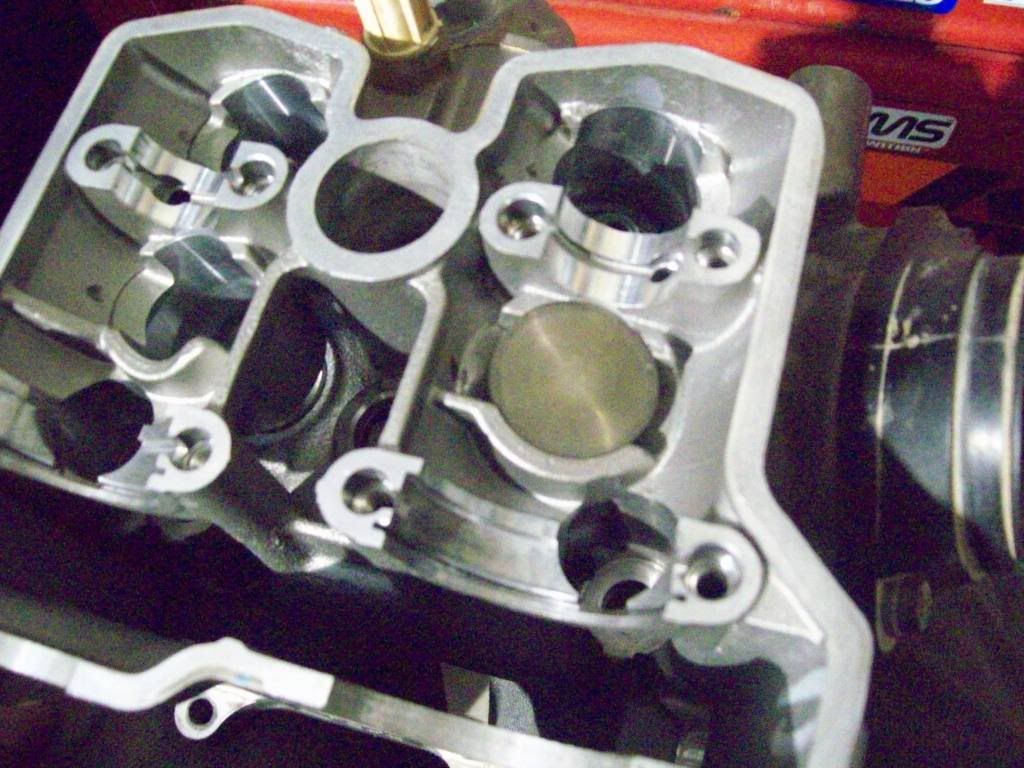

suzuki LT-r450 head (oh man, the things i'm doing to this motor.. it'll be REAL fast. too bad it's a customers) bucket on

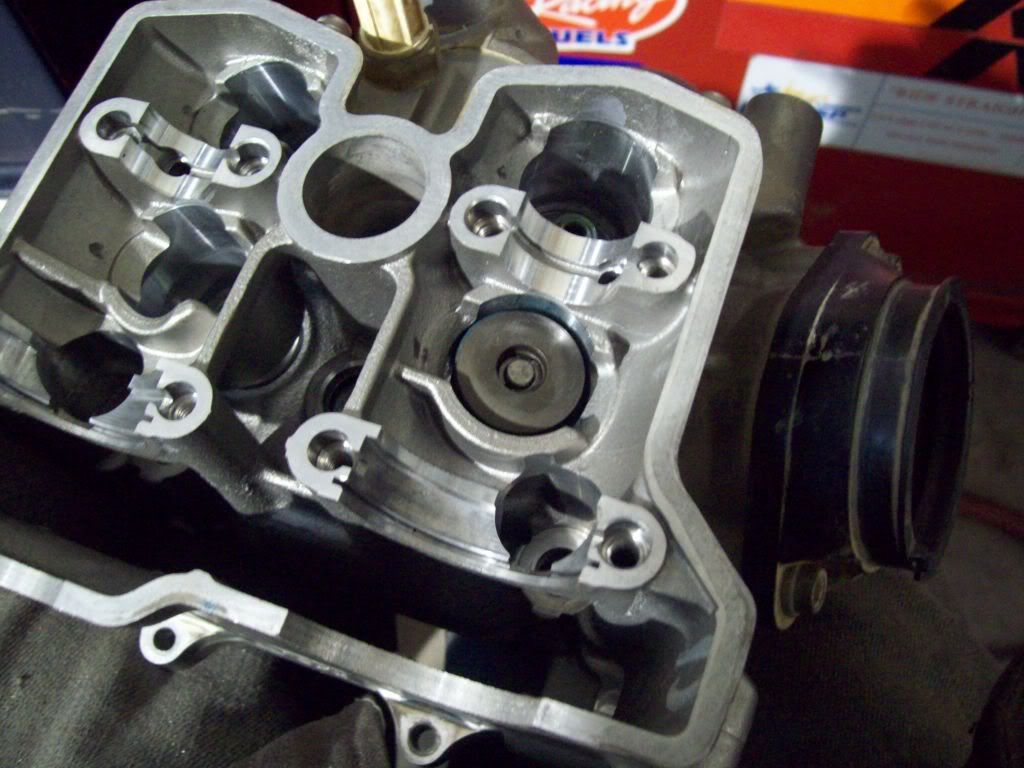

bucket removed. note the teeny tiny retainers

when done right, the retainers fall right into the ipe and stay. Beautiful!!

thats it for now.. i'm sure i'll be building more crap as i see fit. i'm stuck with this darn flux core mig machine at the shop.. sad, but it's better than nothing, even tho i despise flux core.http://kawispeed.com/ -moderator and tech deluxewww.myspace.com/trickortrack -cuz i have no life

Reply:whitehendrix I like the axle tool, i could use one for my bike! the motion pros are expensive. Very creative tools guys!

Reply:Magnetic Mechanic,That knife has layers of steel that I then twisted to get the look you see. It took about 40 hours to make that knife, most of it was making the damascus, maybe 30 hours the rest to make the knife.

Reply:

Originally Posted by ed mac

needed to bend rebar for a job didnt want to spend $39.00 for a bender

Reply:Nice job on the special tools whitehendrix. I'm not into bikes but fully understand the benefit of the alignment tool you've made due to your excellent explanation of how it's used. I'm very familiar with those valve spring compressors and your adapter is a great example especially the fact that it catches the valve locks so you don't have to go chasing them. BTW - special tools don't always have to look pretty just work as intended.

On another note - don't forget to resize your photos so they fit when displayed. Your words get cut off when you don't and it raises havoc for those on dial-up.

MM200 w/Spoolmatic 1Syncrowave 180SDBobcat 225G Plus - LP/NGMUTT Suitcase WirefeederWC-1S/Spoolmatic 1HF-251D-1PakMaster 100XL '68 Red Face Code #6633 projectStar Jet 21-110

Save Second Base!

Reply:Brake bleeder

Attached Images

A butterfly without wings, is just an ugly bug

Reply:

Originally Posted by Magnetic Mechanic

Brake bleeder

Reply:setting up a 12x20 garage in a box from northern toolneeded a to set the anchors

Attached Images

Reply:3 more pics

Attached Images

Reply:

Originally Posted by duaneb55

More info please. |

|