|

|

So...............like I started about mid morning getting hooked up. And, I'm just about half an hour away from actually leaving the yard

Baler's been idle for about over a year, and it takes a bit of TLC to get it ready to rumble.

Oh yeah..........it's toast. Had to beat it off the baler with a sledge because it no longer raises because the thing is so bent.

Replacement in order I guess.

Where it pins on the baler, it's just mildly tweaked.In my defense...........I'm getting old, and forgetful. Kinda need to let it off the jack before ya take off with it

I forget what these high jacks run, but it ain't cheap. So, it's not just a go to the store and buy another one kinda thing.More crap to deal with I guess. Sort of need to have it to drop the baler off the tractor

Reply:Wow, if you only knew someone who knew how to work with metal!

Reply:I've done that before! Should have backed up a little to straighten it up!

Reply:Getting old is not for sissies. you either get old or see what the grass looks like from the other side

Oh and I know the getting old feeling is like (78)

DIY CNC Plasma table USB BOB Price THCHypertherm 65Everlast PowerTig 255 EXTMiler 180 Mig13" metal latheMill/ DrillECT, ECT,

Reply:If that were mine, I would replace it with a hinged leg that operates like the landing gear on a logging trailer.

just drop the landing gear, move the tractor, the baler is lifted.

No jack screwing, no fragile jack to damage,, and a simple pin hinged leg is easy to make, and indestructible!! Those logging guys hook, and unhook loaded trailers ALL the time, if they had crank landing gear, it would be in the shop constantly for repair.I was amazed to see how easy the trailers hooked, and unhooked.

PLUS, those guys driving the logging trucks are not the easiest on equipment.

I would bet you could drive away with the hinged landing gear still down, and nothing would be damaged!!

Reply:

Originally Posted by SweetMK

If that were mine, I would replace it with a hinged leg that operates like the landing gear on a logging trailer.

just drop the landing gear, move the tractor, the baler is lifted.

No jack screwing, no fragile jack to damage,, and a simple pin hinged leg is easy to make, and indestructible!! Those logging guys hook, and unhook loaded trailers ALL the time, if they had crank landing gear, it would be in the shop constantly for repair.I was amazed to see how easy the trailers hooked, and unhooked.

PLUS, those guys driving the logging trucks are not the easiest on equipment.

I would bet you could drive away with the hinged landing gear still down, and nothing would be damaged!!

Reply:Almost all semi tractors now have air ride with a dump valve. In a perfect world even normal landing gear would only have high range.

Reply:Now the day is totally over

Rolled one bale, chamber filled to proper diameter, and the actuator was supposed to move the twine arms down to feed twine underneath the rolling bale.........................NOT ONE DAMN THING HAPPENED

Brought the baler back up to the house to try and figure it out.The actuator motor is good. It will run if you jump the contacts that the two black relays mount to. The motor operates in forward, and reverse, when the relays somehow change the current polarity. I can make it run both ways by jumping the grounds on either relay, but neither relay will work on its own, or together.We blew the afternoon trying to figure it out. And I have hay on the ground that's now been down for 48hrs as of 7:00PM today. It's rapidly drying out to be nothing but crap. I have to get rolling by tomorrow.There are two small (low voltage) wires that come into each relay. I assume these are from the controller in the cab that's linked to the computer in the baler. These wires have to be the ones that activate the coil, close the switch, and allow full 12v to flow through the switch.I guess I have to determine which wires activate the relay,, and which is which, polarity wise. Then I can determine which way the stupid switch is supposed to work to extend/retract the ram on the actuator. Both relays click at the same time when the switch is thrown (there's a manual switch that can override the computer if you want to feed twine manually, or have to reset the arms when a bale doesn't wrap right). If I can figure out the direction the switches work, I can maybe figure out what's wrong.The switch in the cab is a toggle switch that lowers, or raises, the twine arms. A single toggle that works in both directions, and has a neutral middle position.Only 2 wires go to the motor, so there's switching being done at the relays to reverse the current.THIS IS WHY WE'RE ALWAYS BEHIND THE 8 BALL.

Reply:As a veteran of many electronic truck engine troubles, check all of your electrical grounds. Not just tight but clean. If grounding the relay triggers operates the relay, the manual override switch probably has the center terminal connected to ground. Kind of like Kenworth did with their dash switches, if the panel ground wasn't good nothing controlled by the relays worked. I see rusty bolts, etc. where your relay box mounts to the cab. A PowerProbe is your friend for stuff like this.

Reply:

Originally Posted by 12V71

As a veteran of many electronic truck engine troubles, check all of your electrical grounds. Not just tight but clean. If grounding the relay triggers operates the relay, the manual override switch probably has the center terminal connected to ground. Kind of like Kenworth did with their dash switches, if the panel ground wasn't good nothing controlled by the relays worked. I see rusty bolts, etc. where your relay box mounts to the cab. A PowerProbe is your friend for stuff like this.

Reply:

Originally Posted by 12V71

As a veteran of many electronic truck engine troubles, check all of your electrical grounds. Not just tight but clean. If grounding the relay triggers operates the relay, the manual override switch probably has the center terminal connected to ground. Kind of like Kenworth did with their dash switches, if the panel ground wasn't good nothing controlled by the relays worked. I see rusty bolts, etc. where your relay box mounts to the cab. A PowerProbe is your friend for stuff like this.

Reply:Ya know................like you said........I might have continuity from the relay box down to the motor, but not back up to the switch in the cab!!!!!

Reply:Sam, if indeed that cab switch grounds the relay trigger coils, it should show power at the two outer terminals and the center terminal would be grounded. I don't know if your switch is SPDT or DPDT (never worked on a round baler) but throwing the switch will make the terminal opposite the toggle position go dark when it grounds.

Reply:So far, I've been working from the motor back to the relay box. I'll work from the relay box up to the cab unit tomorrow morning

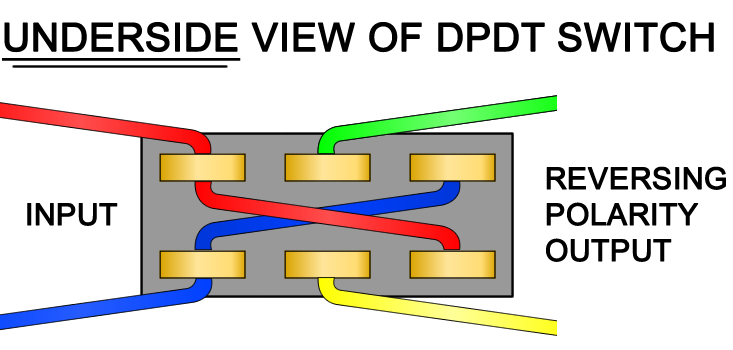

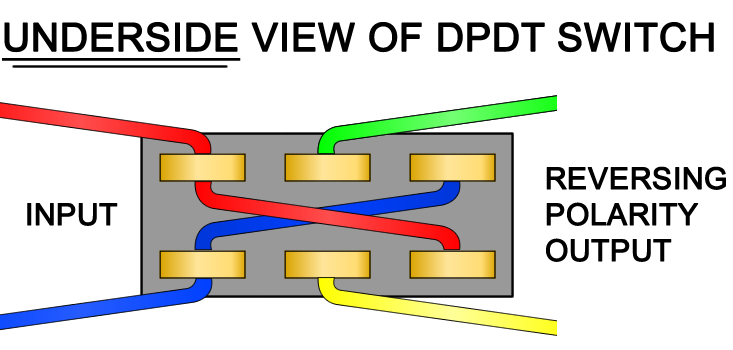

Reply:This is how you wire a double pole, double throw switch to reverse a DC motor, with only 2 wires.

The yellow and green go to your motor.

Reply:

Originally Posted by farmersammm

Now the day is totally over

Rolled one bale, chamber filled to proper diameter, and the actuator was supposed to move the twine arms down to feed twine underneath the rolling bale.........................NOT ONE DAMN THING HAPPENED

Brought the baler back up to the house to try and figure it out.The actuator motor is good. It will run if you jump the contacts that the two black relays mount to. The motor operates in forward, and reverse, when the relays somehow change the current polarity. I can make it run both ways by jumping the grounds on either relay, but neither relay will work on its own, or together.We blew the afternoon trying to figure it out. And I have hay on the ground that's now been down for 48hrs as of 7:00PM today. It's rapidly drying out to be nothing but crap. I have to get rolling by tomorrow.There are two small (low voltage) wires that come into each relay. I assume these are from the controller in the cab that's linked to the computer in the baler. These wires have to be the ones that activate the coil, close the switch, and allow full 12v to flow through the switch.I guess I have to determine which wires activate the relay,, and which is which, polarity wise. Then I can determine which way the stupid switch is supposed to work to extend/retract the ram on the actuator. Both relays click at the same time when the switch is thrown (there's a manual switch that can override the computer if you want to feed twine manually, or have to reset the arms when a bale doesn't wrap right). If I can figure out the direction the switches work, I can maybe figure out what's wrong.The switch in the cab is a toggle switch that lowers, or raises, the twine arms. A single toggle that works in both directions, and has a neutral middle position.Only 2 wires go to the motor, so there's switching being done at the relays to reverse the current.THIS IS WHY WE'RE ALWAYS BEHIND THE 8 BALL.

Reply:

Originally Posted by SweetMK

This is how you wire a double pole, double throw switch to reverse a DC motor, with only 2 wires.

The yellow and green go to your motor.

Reply:Older electronics and weather are why I went back to drills from the air seeder. Need that puppy under some kind of cover, even if it's just a crude roof on poles. Your wet summer has had it's impact.The harder you fall, the higher you bounce...250 amp Miller DialArc AC/DC StickF-225 amp Forney AC Stick230 amp Sears AC StickLincoln 180C MIGVictor Medalist 350 O/ACut 50 PlasmaLes

Reply:

Originally Posted by whtbaron

Older electronics and weather are why I went back to drills from the air seeder. Need that puppy under some kind of cover, even if it's just a crude roof on poles. Your wet summer has had it's impact.

Reply:

Originally Posted by farmersammm

Now the day is totally over

The switch in the cab is a toggle switch that lowers, or raises, the twine arms. A single toggle that works in both directions, and has a neutral middle position.Only 2 wires go to the motor, so there's switching being done at the relays to reverse the current.THIS IS WHY WE'RE ALWAYS BEHIND THE 8 BALL. |

|