|

|

So I do a lot of "wrought iron" railings, fencing and gates, so I figure I'll share my work, for anyone interested. Questions, comments and criticisms are all welcome. So I'll start with some projects I did last year, and keep updating as I do more work. Enjoy!

http://www.philswelding.com

Reply:So here's a pool fence I did in greenwich, lovely property.

Last edited by MetalMan23; 02-02-2016 at 08:46 PM.

http://www.philswelding.com

Reply:Here's a topper fence along a curved stone wall

I bent the horizontal rails with the HF hydraulic tubing bender with some custom dies I made

http://www.philswelding.com

Reply:Ok here's a gate a made to match some existing stuff. Again this one's in greenwich , The last one ^^^^^ was in greenwich too

Lol a couple days before the install, after it was all painted, I realized that I had forgotten to put the knuckles in the middle of the pickets, so I ordered some snap on plastic ones, luckily they matched, and they blend in too

http://www.philswelding.com

Reply:You killed it on that curved one. They all look really nice and are all money makers.

Reply:

Originally Posted by Bob

You killed it on that curved one. They all look really nice and are all money makers.

Reply:Nice job, matches the homes .

Reply:

Originally Posted by BD1

Nice job, matches the homes .

Reply:I like your work - nicely done

Dave J.Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~ Syncro 350Invertec v250-sThermal Arc 161 and 300MM210DialarcTried being normal once, didn't take....I think it was a Tuesday.

Reply:Nice work. Nice curves. Plastic is great in right situation and fast and fits well and doesn't rust..

Reply:

Originally Posted by MinnesotaDave

I like your work - nicely done

Reply:Mick120, tapwelder, thanks I'll have some more pics tomorrow.

http://www.philswelding.com

Reply:You are working in the right part of the state. Nice work.Miller 211Hypertherm PM 451961 Lincoln Idealarc 250HTP 221 True Wisdom only comes from Pain.

Reply:nice. i tell customers, theres a difference between a "welder that makes a fence, and a fence man that welds". around where i live, it is industry standard for fence co's, to not weld the underside of the bottom tube rail. the co i once worked for, it was also noted in there contracts in sorta fine print. its a almost guaranteed rott out in time, especially on fences running through grass w/ sprinklers. i try to avoid fence work these days, other than repairs, or small jobs when i get roped into it for somebody i know. i feel i done enough to last me the rest of my natural life. back in the early aughts, when marlboro and all the other tabaccoo companies got sued, or settled out, the public schools got a chunk of that, and it seemed every public school was replacing there chain link fences w/ ornamental iron panels that were powder coated over galvanized tubing. i could get into living in that house

Reply:Hey Metalman,The curved rail looks great!What material are you using to anchor in stone?Thanks,Mike

Reply:I bent the horizontal rails with the HF hydraulic tubing bender with some custom dies I made[. You took what usually is a boring looking everyday railing and turned it into something very attractive with those curves! Well done!!!

Reply:123weld, thanks that's a good point, I'm a welder who makes fencing. I try to make the best quality I can. d110pickup, i use anchoring cement, comes in 1 gallon buckets, it's a type of hydraulic cement, expanding slightly as it cures, which only takes about 45 min. Now I've neen using a blend of anchoring cement and water stop cement, it hardens in about 10 min, and cures in about 45 min. BrianC, thanks! I love it when someone is willing to pay for radius/ curved stuff, it's definitely a challenge that I enjoy. and it really adds a level of quality to the job.

http://www.philswelding.com

Reply:Ok so I found some pics of the radius stuff, this house had 2 porches off the back of the second floor.

And here's some pics in summer when I came back to touch up the paint

This job was fun to do, my first real radius job. I took a template with a price of plywood, and again I used the HF tubing bender with custom dies to bend the caprail the hard way.

http://www.philswelding.com

Reply:

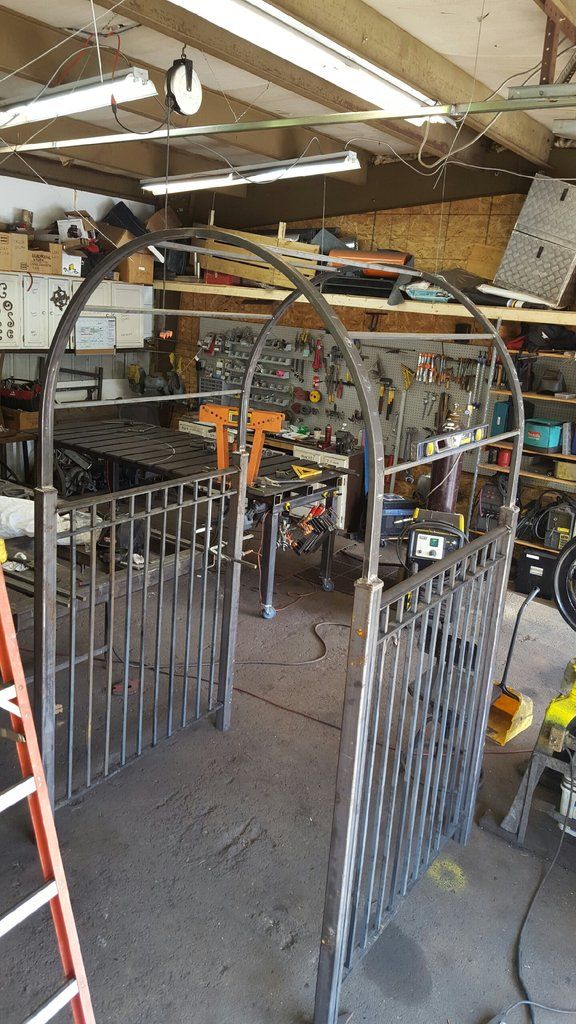

Here's something I'm working on today. Still have to drill and tap for hinges, and paint

http://www.philswelding.com

Reply:Beautiful work, thanks for sharing.

Reply:My pleasure, Here's a couple more Gates:

And here's some interior gates, I did 3 inside this customers house, to help keep dogs out of certain rooms

http://www.philswelding.com

Reply:Did you use the HF bender or roller for your radii?

Reply:I use the their regular bender for the easier stuff, and for the hard stuff, like tubing or cap rail the hard way, I use their hydraulic tubing bender, Here's a pic of my cap rail dies in the bender:

And here's the bender set up with my square tubing dies:

I really should be using a roller for the tubing, but I don't have 2" dies for my pyramid roller. So this works.

http://www.philswelding.com

Reply:If the piece o steel I'm bending is not too heavy I'll just stick it between 2 slats of my old table, and pull/jump on it to get the bend. I've done a lot of bending like that, irregular curves and such.

http://www.philswelding.com

Reply:Damn Nice Work!Miller TrailBlazer 251Miller HF-250-1Miller MaxStar 150 STLHyperTherm PowerMax 380 plasmaLincoln PowerMig 180Millermatic 252Miller Diversion 180

Originally Posted by MetalMan23

Ok here's a gate a made to match some existing stuff. Again this one's in greenwich , The last one ^^^^^ was in greenwich too

Lol a couple days before the install, after it was all painted, I realized that I had forgotten to put the knuckles in the middle of the pickets, so I ordered some snap on plastic ones, luckily they matched, and they blend in too

Reply:

Originally Posted by wagin

Damn Nice Work!

Reply:I see, when you said bender I thought you meant roller but hadn't considered that you were making increments and making slight bends, looks really nice! I bet the math for the spacing and bend degrees/figuring for springback was fun, haha. We use the HF roller for radiusing tubing, there's really not much of the original roller left though. Rather than do the add on wings we made new bigger sideplates for it and went with a bottle jack for the downfeed instead of the screw. Driven with a HF pipe threader we rolled 1/8" wall 2" square tube to a 7' radius.

Reply:

Originally Posted by Sharon Needles

I see, when you said bender I thought you meant roller but hadn't considered that you were making increments and making slight bends, looks really nice! I bet the math for the spacing and bend degrees/figuring for springback was fun, haha. We use the HF roller for radiusing tubing, there's really not much of the original roller left though. Rather than do the add on wings we made new bigger sideplates for it and went with a bottle jack for the downfeed instead of the screw. Driven with a HF pipe threader we rolled 1/8" wall 2" square tube to a 7' radius.

Reply:The problem with 14ga is once you start trying to go that tight it starts to crinkle on the side that's trying to shrink. We were planning on using it for that project but had to go to 1/8" to roll without crinkling. We cobbled together some dies using the the existing HF ones, with a few add-ons. We have them pinned to the shaft with 5/16" roundbar but rolling stuff that tight will shear through the pin after a while.

Reply:Yeah that's a problem, that's why I use a section of pipe for my inner die, it crimps the inside of the tubing and prevents it from messing up the sides.

http://www.philswelding.com

Reply:Here's an arbor I made a couple months ago, using the same method of bending the curves: I did the arbor to match the existing pool fence

This thing was heavy, I built the top curved section separate and assembled it on site. Had it powder coated tooLast edited by MetalMan23; 02-04-2016 at 08:05 AM.

http://www.philswelding.com

Reply:Nice work Phil, the arbor look real nice

Reply:Awesome work. I've always want to do stuff like that. I oils like to try and do some scroll work. Sent from my iPhone using Tapatalk

Reply:

Originally Posted by Harry72

Nice work Phil, the arbor look real nice

Reply:

Originally Posted by beaner

Awesome work. I've always want to do stuff like that. I oils like to try and do some scroll work. Sent from my iPhone using Tapatalk

Reply:I would like to make some tools. ( when time permits) I was doing tool and die for 16 years now running a Cnc mill. I'm also a welder. My brother in law runs a haas Cnc lathe right beside me at work. We have access to a full fab shop with Cnc breaks and lasers. So I capable of making tooling just so busy! My brother in law and I would like to start our own shop some day soon. But the stuff you do is great and masterful and artistic. Sent from my iPhone using Tapatalk

Reply:

Originally Posted by beaner

I would like to make some tools. ( when time permits) I was doing tool and die for 16 years now running a Cnc mill. I'm also a welder. My brother in law runs a haas Cnc lathe right beside me at work. We have access to a full fab shop with Cnc breaks and lasers. So I capable of making tooling just so busy! My brother in law and I would like to start our own shop some day soon. But the stuff you do is great and masterful and artistic. Sent from my iPhone using Tapatalk

Reply:Here's some fencing, with a matching gate, I never got a good picture of the gate.

Here's some smaller miscellaneous jobs:

Last edited by MetalMan23; 02-05-2016 at 03:01 PM.

http://www.philswelding.com

Reply:Oh yeah, check this out, it's an entertainment center. Steel frame, cherry shelves, and stainless cables and hardware:I used 1" square tubing 16ga for the frame, and 1/4"x2" for the vertical straps. Here's the frame hanging in my shop, after painting

Mounted on the wall, with stainless hardware and wood shelves attached:

And here it is with the TV and other stuff all set up:

This was a pretty cool project, the interior designer basically gave me an idea, and I had to design and fabricate from scratch. Also adding a wood element really increased the difficulty. I wanted it to look like it was suspended from cables, kinda like a bridge.

http://www.philswelding.com

Reply:I make a lot of custom strap hinges for a fence company I work with.

I weld the 'badass' ball bearing hinges to the strap, to make hinges that are rated for like 1500-2000lbs

http://www.philswelding.com

Reply:Here's a gate I put into a bluestone patio, after I anchored it in, the guy I was working for realized he told me the wrong location. Lol so I had to take it out after I took some pics, I told him his guys could re-drill the holes and anchor it, it was Friday and I was going to newfoundland the next morning.

http://www.philswelding.com

Reply:So you guys can see I do a lot of railings, I'm finally figuring it out after being in business since late 2012Hope you enjoy the pics

http://www.philswelding.com

Reply:Here's one of the most complicated railings I ever fabricated, just because the lack of a bottom rail, took me way longer than it should have, They wanted all the pickets drilled into the bluestone, and a radius to boot.

http://www.philswelding.com

Reply:Don't look too closely at that last pic^^^ you might see that the posts aren't perfectly level. 😎

http://www.philswelding.com

Reply:Wow,Brilliant work, dude!

Reply:

Originally Posted by C. Livingstone

Wow,Brilliant work, dude!

Reply:Nice work. How did you jig and transport that last rail. I find it difficult to fab and handle any rail without a lower horizontal rail.

Reply:

Originally Posted by tapwelder

Nice work. How did you jig and transport that last rail. I find it difficult to fab and handle any rail without a lower horizontal rail.

Reply:great railings! |

|