|

|

Well this question has been bothering me for a while I hear about 6011 all the time I generally run 6010 as a root pass on an open root joint and then hot pass and cap with 7018. A few months ago I had a problem on a weekend had to go to a Home Depot or something to get some 6010 they only had 6011. I thought it ran like dog**** compared to the Lincoln pipeliner 6010 I normally run. Does 6011 just run bad or was this just cheap rod that ran like crap? If its 6011 in general why is it so popular, is everyone running it on AC?

Reply:

Originally Posted by 426hemi

Well this question has been bothering me for a while I hear about 6011 all the time I generally run 6010 as a root pass on an open root joint and then hot pass and cap with 7018. A few months ago I had a problem on a weekend had to go to a Home Depot or something to get some 6010 they only had 6011. I thought it ran like dog**** compared to the Lincoln pipeliner 6010 I normally run. Does 6011 just run bad or was this just cheap rod that ran like crap? If its 6011 in general why is it so popular, is everyone running it on AC?

Reply:It's quite tough for us to relate since we weren't there. They run very similar to E6010 on DCEP, just perhaps not quite as smooth. I personally don't think the difference is as you've described, but I have a few tins of Lincoln Pipeliner 6010 is a very good rod that runs nice and smooth.

1st on WeldingWeb to have a scrolling sig!

Reply:6010 runs better than 6011. That said, last time I bought electrodes, I ended up buying 6011 on accident. Grabbed the wrong box and didn't notice till I was checking out. I didn't bother to go over and swap them out. They run fine. They're Hobart 3/32 6011. I've used Hobarts in 1/8" and 5/32", too. Same thing. They run fine, just more "harsh" than 6010. When I say "more harsh", it isn't that bad. I was welding 14 gauge with those 3/32" rods the other day and they got the job done just fine.

Reply:

Originally Posted by Oscar

It's quite tough for us to relate since we weren't there. They run very similar to E6010 on DCEP, just perhaps not quite as smooth. I personally don't think the difference is as you've described, but I have a few tins of Lincoln Pipeliner 6010 is a very good rod that runs nice and smooth.

Reply:

Originally Posted by 52 Ford

You talk a sales rep into giving you those rods, too???

Reply:

Originally Posted by Oscar

Nah I got those a my Home Depot actually. Pricing mistake (that they had for the longest time) allowed me and a few others here to get a few tins before they caught on to us. $70 a tin for 50lbs of Pipeliner.

Reply:Interesting cant say Ive ever stick welded with my inverter at home I use it as a mig and a tig welder exclusively working on my little projects at home. Im going to try some 6010 and see? I stick weld with an engine driven unit on my service truck at work. Im not saying I had to grind that 6011 weld out just didnt run like I am used to. A lot of spatter and just not smooth but the end result was satisfactory. I just was curious why it was so popular considering it doesnt run as good I think BrooklinBravest might be on to something with inverter machines not being able to run 6010 these are extremely popular these days.

Reply:

Originally Posted by 426hemi

Interesting can’t say I’ve ever stick welded with my inverter at home I use it as a mig and a tig welder exclusively working on my little projects at home. I’m going to try some 6010 and see? I stick weld with an engine driven unit on my service truck at work. I’m not saying I had to grind that 6011 weld out just didn’t run like I am used to. A lot of spatter and just not smooth but the end result was satisfactory. I just was curious why it was so popular considering it doesn’t run as good I think BrooklinBravest might be on to something with inverter machines not being able to run 6010 these are extremely popular these days.

Reply:It simple.E6011 can used with AC or DCE6011 can only be used with DC typically with heavy duty welder.If both AC and DC types you use E6011. Dave

Originally Posted by 426hemi

Well this question has been bothering me for a while I hear about 6011 all the time I generally run 6010 as a root pass on an open root joint and then hot pass and cap with 7018. A few months ago I had a problem on a weekend had to go to a Home Depot or something to get some 6010 they only had 6011. I thought it ran like dog**** compared to the Lincoln pipeliner 6010 I normally run. Does 6011 just run bad or was this just cheap rod that ran like crap? If its 6011 in general why is it so popular, is everyone running it on AC?

Reply:

Originally Posted by BrooklynBravest

Dont quote me but I believe 6011 is designed to run in place of 6010 on inverter machines. For whatever scientific reason 6010 doesn't run on inverters properly, so 6011 exists. I assume vice-versa 6011 doesn't like to be ran on transformer machines.

Reply:

Originally Posted by 12V71

Actually 6011 is made with arc stabilizers that make it suitable for low voltage AC machines. 6010 relies on a stable DC arc from a good machine with good welding voltage.

Reply:

Originally Posted by Oscar

Nah I got those a my Home Depot actually. Pricing mistake (that they had for the longest time) allowed me and a few others here to get a few tins before they caught on to us.

Reply:I bought 1 tin a month for like 8 months, lol. In hindsight, I should have bought 10 tins per month, lol. How many did you buy?

1st on WeldingWeb to have a scrolling sig!

Reply:HD sells AC/DC welders so they sell AC/DC rods. That's why some places of big box stores only sell 7018 AC only rods

Reply:6011's were made to run on a AC buzz box, 6010 runs on a DC welder. To me 6011 is a softer/less penetration, on a DC machine.We've done so much, for so long, with so little. Were now qualified to do anything with nothing !

Reply:Pretty much my experience too. I use a lot of the Murex/Lincoln 6011C for irrigation repairs in thin, rusty, or galvanized pipe. Very smooth, less penetrating arc that still burns good at lower amps. I can run 1/8" all the way down to 70 or less and still get a weld.

Reply:It was my understanding that 6011 had more iron powder to assist in getting an arc started and maintaining it on older AC machines that were short on OCV, don't know if that's true but it's what I've read. That offers no explanation about 6010 on some inverter machines, mine runs it just fine.NRA LIFE MEMBERUNITWELD 175 AMP 3 IN1 DCMIDSTATES 300 AMP AC MACHINELET'S GO BRANDON!"Those who would give up essential Liberty, to purchase a little temporary Safety, deserve neither Liberty nor Safety. BENJAMIN FRANKLIN

Reply:

Originally Posted by Oscar

I bought 1 tin a month for like 8 months, lol. In hindsight, I should have bought 10 tins per month, lol. How many did you buy?

Reply:6011 is an AC / DC rod 6010 has variables for instance lincoln 6010 { AWS designation } has a Lincoln designation 5P the P stands for iron powder { in the flux } which makes it weld a little better less spatter less arc blow if you had ever run straight 5 you would be able to see the difference so when your comparing it is important to note all your variables one thing you will notice is that the rod with iron powder in it will usually let you weld with more amps or OCV

Reply:

Originally Posted by Leogl

6011 is an AC / DC rod 6010 has variables for instance lincoln 6010 { AWS designation } has a Lincoln designation 5P the P stands for iron powder { in the flux } which makes it weld a little better less spatter less arc blow if you had ever run straight 5 you would be able to see the difference so when your comparing it is important to note all your variables one thing you will notice is that the rod with iron powder in it will usually let you weld with more amps or OCV

Reply:

Originally Posted by CAVEMANN

It was my understanding that 6011 had more iron powder to assist in getting an arc started and maintaining it on older AC machines that were short on OCV, don't know if that's true but it's what I've read. That offers no explanation about 6010 on some inverter machines, mine runs it just fine.

Reply:

Originally Posted by Jack Ryan

I'm no expert on Lincoln electrodes but I think the 'P' means pipe and I haven't seen anything that would indicate that 5P or 5P+ contains iron powder in the flux.Where did you find that?

Reply:Local grain mill was wood in 1963 when it burned to the ground.They rebuilt it with all steel construction. Only welder I saw was a monster Marquette AC tap welder. The wooden boxes the 5/32" 1109 rods came in must have been 200 or more pounds.It was also a farm store & the only rod they had to sell were the 1109 sold by the pound from bulk. I'd say most of what I was buying in the mid seventies was 10 years old left over from building the mill. Eventually, I learned that 1109 was 6011 read upside down.I bought an AC welder in 1974 & found the 5/32 6011 worked very well except vertical, it ran like an ice cream cone on a hot summer day. It is spattery with a lot of BBs.Years later I got a DC welder & first tried 6010. Welder, or rod, I didn't know, it ran smoother. I later had the pleasure of using a Miller Dialarc & learned my Twentieth Century 295 wasn't the best welder. 2011 has "arc stabilizer" in the flux to keep the cloud ionized as flow of current in sine wave AC totally dies 120 times a second. I'll guess potassium, but there may be another ingredient not mentioned.I'm curious if inverters have square wave power which would virtually eliminate the sputtery arc associated with AC welding? I believe it is the low open circuit voltage of modern designed welders makes 6010 difficult to run even on DC. An old transformer welder might have up to 100 volts OCV, where an inverter might be below 50 volts OCV. More voltage makes it easier to establish & maintain an arc. Very short arc keeps the arc voltage low for deeper penetration & longer arc raises voltage for less penetration.An optimist is usually wrong, and when the unexpected happens is unprepared. A pessimist is usually right, when wrong, is delighted, and well prepared.

Reply:

Originally Posted by Willie B

I believe it is the low open circuit voltage of modern designed welders makes 6010 difficult to run even on DC. An old transformer welder might have up to 100 volts OCV, where an inverter might be below 50 volts OCV.

Originally Posted by StandarDyne

I don't think OCV is the issue. My engine drive DC-only welder (Miller Big Blue 251D) has a "fine adjustment" rheostat that varies the OCV from 58 to 88VDC, and I typically run 6010 on the middle tap with fine adjustment rheostat down around 5% (~ 60VDC OCV). I don't know what the arc voltage ends up being, but would guess ~ 30VDC. And that machine runs 6010 (and 7018) nicer than any welder I've ever used. Apparently it makes 3-phase power, then rectifies it...dunno whether that has anything to do with why the arc is so nice. (I understand this is different than, say, an SA200...I think the SA200 is considered a "generator" and my 251D uses an "alternator" ... whatever that means. Supposedly this also makes the brushes last longer than those on an SA200 because less current goes through them or something...)

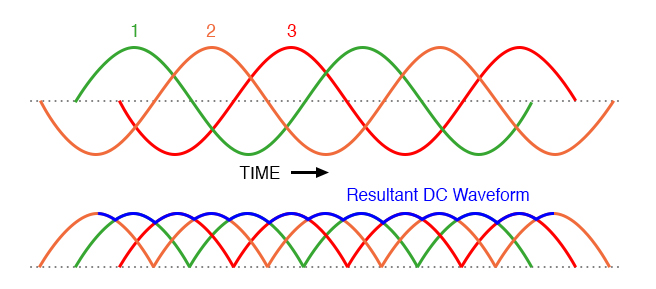

Reply:Examining the finer points of 6010, 6011, and 7018 By Marty Rice June 13, 2006 Article Consumables 2 CommentsEditor's Note: This article first appeared on www.thefabricator.com on April 15, 2002.The student was terrified."They're giving us 6011 instead of 6010!" he whispered."Don't worry, it's just like 6010," I reassured him.We were at our regional Vocational Industrial Clubs of America (VICA) competition. My students just had been debriefed and were going out to the shop to begin their welding skills contest. They calmed down and ended up sweeping first through fourth places.I teach high school structural welding. I had stressed 6010 and 7018 while neglecting to inform the students of the other electrodes out there. In high school classes I try to stick to the fundamentals. I've been welding 25 years, and I still feel overwhelmed when I think of all the different processes out there.On the way home from our contest, I explained that although 6010 and 6011 were different electrodes, their similarities outweighed their differences. Both are fast-freeze rods, meaning that the weld puddle changes from liquid to solid rapidly. They also have deep penetration; produce a flat, rippled bead; and leave little slag. They are great for all positions, and they are used primarily by pipefitters, pipeliners, and boilermakers.Although I've almost exclusively used 7018 as a structural welder, I've also burned my share of 6010 and 6011. These two rods are used for many applications in the field. They do have technical differences, such as different flux compositions; however, I'm going to give you my nontechnical, self-proclaimed expert opinion of the rods. I'm proclaiming myself an expert because I believe using the rods while standing on scaffolds, balancing on 2-inch beams 30 stories high, hanging in boatswain's chairs, lying upside down under vessels, and cramming myself claustrophobically into vessels while welding qualify me.I've also fallen off some of those buildings, but that's another story.6010 and 6011 ElectrodesThe "60" in 6010 means 60,000 pounds' tensile strength (the ability to resist being pulled apart) per square inch. The "1" means it can be run in any positionflat, horizontal, vertical, or overhead.The last number, 0 or 1, is some kind of technical jargon that I have never used in my 25 years as a journeyman or instructor. But for you engineer types, you know it has to do with flux composition, slag type, and power supply.Both 6010 and 6011 are good electrodes. In my opinion, they are the only rods to tack with. They strike very easily and leave little slag to chip off. They also are very good when you need full penetration. They are a prime choice for welding decking, an application in which you must penetrate through the gauge metal into the joist or beam.Crank up the machine to warp 10, and you have a portable torch. It doesn't cut that pretty, but it gets the job done in a pinch when you don't have access to an oxyacetylene rig and need to cut something in a hurry. Make sure the area around you is clear, especially below if you are working up high. Cutting with these electrodes produces big-time sparks and large globs of molten metal.6011 runs on AC and direct current electrode positive (DCEP), while 6010 runs only on DCEP. This gives 6011 an advantage if you have an AC-only machine. I have found, and think most welders will agree, that 6010 runs more smoothly. The slag chips off better than 6011, and this is one reason it is used more often than 6011 in root passes on pipes.Another advantage of these electrodes is the speed at which they burn. This makes them ideal for welding joists and bridging, especially the stiffening angle going from joist to joist for bracing. These two electrodes have enough strength to do the job and are much faster than 7018. They run great downhill passes where not a lot of penetration or structural strength is required.7018 ElectrodesThe 7018 is the backbone of structural welding. This rod runs completely different from the 6010 and 6011 rodsit is much smoother and easier. More of a "drag" rod, the 7018 is also referred to as a low-hydrogen, or "low-high," rod in the field. The flux contains almost no hydrogen, and the rod produces smooth, strong welds that are very ductile.For this reason, these rods are used extensively in structural welding. I've used them on shopping centers, factories, powerhouses, nuclear weapons assembly plants, high-rise office towers, dams, and bridges. I've also used them on about a billion "neighbor-friend" projects.The key word for the 7018 is versatility.A 7018 rod literally should be dragged across the metal when welding. Along with dragging, a welder can weave it back and forth or oscillate it to feather it in on both sides. In vertical welding, some welders will count repetitions on each side of the weld pool, but this is a really bad habit to get into. As my old instructor used to scream into my ear, "Relax your hand and watch the puddle!" As long as you watch the puddle and relax your hand, you should be able to see and feel it tie into the steel. Counting doesn't guarantee a good tie-in; seeing and feeling do.Shops, field welders, and home hobbyists often do not store 7018 rods properly. Being a low-hydrogen rod, 7018 requires an environment in which no moisture is allowed to get into the flux.This is achieved by using a rod oven. I have seen all sorts of ovens used. I once saw a refrigerator that was converted into a makeshift oven by placing a high-wattage light bulb inside. This is done all too often and is in no way acceptable7018 rods should be kept at 250 degrees F. If they are out in the open for less than four hours, they can be rebaked at 700 to 800 degrees F for an hour.It all depends on the code (for instance, AWS D1.1 92 Steel Structural Welding Code) and what you are welding. I've seen only a few jobs in which the rods were stored correctly, if at all.Another common mistake is opening the wrong end of the box. Another is throwing the boxes around during storage. Both break the flux off the rods. These damaged rods usually end up being wasted. If the flux is broken only off the tip, they can be long-arced and used. But if the flux is broken in other areas, the rod is useless. It's bad enough tossing away rods only halfway burned, but it is worse to throw away rods that have never been used at all.If you were to ask a Ford fan, Chevy fan, or Dodge fan which truck is the best, you'd be there for hours. All three are good trucks with different pros and cons.The same can be said of the different brands of rod. When it comes down to it, almost all are good. Some seem to run more smoothly; like most welders, I do have a preference, but can make do with any of them.The 6010 and 6011 rods intimidate many first-time welders. Because they require more manipulation, they are a bit harder to run than 7018.Many instructors teach only the "whip method," while others believe only in "circles" for rod manipulation. I don't care if you stand on your head gargling peanut butter, as long as your weld is sound.

Reply:

Originally Posted by Willie B

Higher voltage before striking an arc makes it easier to get it going.

Reply:

Originally Posted by Willie B

I'm curious if inverters have square wave power which would virtually eliminate the sputtery arc associated with AC welding?penetration.

Reply:delete

Reply:Oscar: "Are you asking specifically about DC inverter stick welders??"Not DC, DC is near enough to constant, ionization won't be lost at cycle reversal as it could with AC sine wave.The only inverter stick machine I have is Miller Dynasty 280DX. I've done only enough stick welding with it to know it works well with 7018 & it makes too much smoke for the place the Dynasty lives. Come to think, I did weld hundreds of 2" long Filets on 1/4" stock & it welded very well with 6010. I haven't tried AC stick at all with it. I believe it does offer square wave AC stick.My stick welding is either with a Lincoln shaped like a 1955 refrigerator, or the Miller Bobcat 250.An optimist is usually wrong, and when the unexpected happens is unprepared. A pessimist is usually right, when wrong, is delighted, and well prepared.

Reply:When Lincoln quit making straight 5 which is what we used on the pipeline and went to 5P we asked what the P stood for they told us iron powder

Reply:

Originally Posted by Willie B

Oscar: "Are you asking specifically about DC inverter stick welders??"Not DC, DC is near enough to constant, ionization won't be lost at cycle reversal as it could with AC sine wave.

Reply:

Originally Posted by Oscar

Inverter AC TIG welders that can also stick weld most likely use square-wave for the AC stick welding side, unless user adjustable from the software.

Reply:

Originally Posted by Willie B

I'd only be guessing what happens in a three phase welder after power is produced in the three phase alternator.

Reply:

Originally Posted by StandarDyne

Something like this, maybe?

Reply:

Originally Posted by StandarDyne

Now ya got me wondering whether my Sync 250, which has squarewave AC for TIG, will also give squarewave for AC stick. I'll have to try some 6010 on AC...

Reply:

Originally Posted by Leogl

When Lincoln quit making straight 5 which is what we used on the pipeline and went to 5P we asked what the P stood for they told us iron powder

Reply:6011 and it's brethren, 6013 offer alternatives to machines that struggle to create a stable arc or have problems keeping the arc lit with a 6010. Some of the cheaper inverter machines will struggle with 6010 or 7014 when it comes to arc behaviors. They also tend to be better performers in some positions and modes on inverters (variability in weld pool behaviors).Rod brand and type may play a role in it's performance. I haven't struck an arc with the new miller machine using rods yet but it's supposed to be worlds better than my asian import for arc behavior.

Reply:

Originally Posted by Oscar

6010 or 6011?

Reply:Wow some great information, I tried running some 6010 with my 211i inverter at home last night it didnt run great compared to the trailblazer on my truck. I have never run stick on it before (its used as a dedicated mig/tig home unit). Hard to strike an arc and had to crank the inductance up all the was just to keep it lit. Had to keep an extremely short arc to keep it lit. Im no expert but it felt like a low voltage issue. Its doubtful one could run a acceptable open root pass with this inverter with 6010. I tried some 7018 with that machine and it ran that great. Very interesting. If I was welding pipe or thick plate with that inverter Id probably TIG weld the open root pass and then run 7018Last edited by 426hemi; 3 Weeks Ago at 12:18 PM.

Reply:

Originally Posted by 426hemi

Wow some great information, I tried running some 6010 with my 211i inverter at home last night it didn’t run great compared to the trailblazer on my truck. I have never run stick on it before (it’s used as a dedicated mig/tig home unit). Hard to strike an arc and had to crank the inductance up all the was just to keep it lit. Had to keep an extremely short arc to keep it lit. I’m no expert but it felt like a low voltage issue. It’s doubtful one could run a acceptable open root pass with this inverter with 6010. I tried some 7018 with that machine and it ran that great. Very interesting. If I was welding pipe or thick plate with that inverter I’d probably TIG weld the open root pass and then run 7018

Reply:

Originally Posted by Willie B

I'm pretty uninformed, but I believe some old big machines run pretty low on closed circuit voltage, but are capable of pretty high amperage. Watts make metal melt. Talking about only volts or amps doesn't say much about heat. Arc length controls voltage with most machines & amperage is regulated by the welder.

Reply:

Originally Posted by Jack Ryan

As I noted earlier, it is not just OCV that is the issue. Those big old machines probably have plenty of available slope and inductance as well.It is true that watts are needed to melt metal but it is also true that voltage is required for gas ionisation to produce an arc. Of course, arc stabilisers in the flux help too.Jack

Reply:The old welders use all copper windings the new welder use aluminum in have transformer. Even most low cost welders in 1960's could run E6011 and E7018. Dave

Originally Posted by Jack Ryan

As I noted earlier, it is not just OCV that is the issue. Those big old machines probably have plenty of available slope and inductance as well.It is true that watts are needed to melt metal but it is also true that voltage is required for gas ionisation to produce an arc. Of course, arc stabilisers in the flux help too.Jack

Reply:

Originally Posted by XMilitary

6011 and it's brethren, 6013 offer alternatives to machines that struggle to create a stable arc or have problems keeping the arc lit with a 6010. Some of the cheaper inverter machines will struggle with 6010 or 7014 when it comes to arc behaviors. They also tend to be better performers in some positions and modes on inverters (variability in weld pool behaviors).Rod brand and type may play a role in it's performance. I haven't struck an arc with the new miller machine using rods yet but it's supposed to be worlds better than my asian import for arc behavior.

Reply:

Originally Posted by albrightree

On the other hand ,Some cheap inverters will run 6010 but not very well, and others are a little bit difficult with even some 6011 types, you have to keep a really tight arc and even then they stick sometimes and go out. Even with the arc force turned up, they still can be difficult Regards

Reply:

Originally Posted by smithdoor

Even most low cost welders in 1960's could run E6011 and E7018. |

|