|

|

I have been able to TIG weld all sorts of Aluminum but best practices with regard to torch setup are still a bit confusing to me. I have heard the following:Do not use a gas lens when TIG welding Aluminum.Use a small cup size.Use a large cup size.Use a gas flow of 30 scfhUse a maximum of 15 scfhetc., etc.I do not presently weld for a living but have TIG welded since the mid-seventies, with a 20 year break in the middle during which time welders changed from 700lb. monsters to PC sized inverters.I have received sound advice on this Forum and have been successful on projects for myself and friends, steel, SS, and Aluminum. Most notably electrode size for thicker (1/4") Al and the use ofbalance and frequency for deeper penetration on thicker sections. I have also adopted the practice of creating a small ball on the end of the Tungsten using an EN of 30 on a solid block. This isprobably a holdover from the transformer days with a pure Tungsten electrode. I thank this Forum.My question:Specifically, are there known best practices for torch setup with regard to cup size/configuration, lens or no lens, etc.? In my limited experience I have been able to make all of them work. My torch is a 17 and I am running with an HTP 221 (air cooled).As always, your input is welcome.

Reply:I think a lot of people say only what they know or have experience of, and it's not always correct. What suits your job might not suit mine, and vice versa.IME aluminium does not need a big cup, nor does it need much gas. I use a no.7 cup on it like i use for 99% of everything. I will change from gas lens to collet if I'm doing a lot, just because a big touchdown is more likely to foul the gas lens, but otherwise, i don't touch a thing.I use the same gas flow for alloy as i would on stainless/carbon steel. IIRC 9 lpm/19-20 CFH. i could turn it down, but honestly, I just don't want to mess with something that isn't broken.That's what works for me

Murphy's Golden Rule: Whoever has the gold, makes the rules.

Reply:Thanks, that's similar to my experience. I change to a "stubby" if into tight places and change electrode diameter with the thickness of the material and the current I think I'll need. For almost everything a collet works just fine. I haven't had issues with gas lens unless, as you've mentioned, I blow it and touch the puddle badly. Have only worked SS for exhaust systems, haven't tried a gas lens on that yet. I set my flow at 15-20 and measure it when switching bottles or just checking.I guess it's just a matter of personal preference.

Reply:I don't feel like I have to change anything in the torch for Alum...Same gas lens, cup, flow, etc.. You have to go way Up in Amperage for the same thickness of course and I also use that higher heat to go Faster (prettier welds

) but the same "practices" apply (long enough post-weld gas flow like you need on SS). CLEANESNESS is more important in Alum but, like with All Tig welding, the details are important and ya can't shortcut on very much anyway.No Balance change for thickness though, freq - maybe (Jody says lower for thicker) and maybe a Tungsten change but same "grind". Really not all that much different!

Reply:I'm not a pro, just a hobby guy like you. I run #7 cup with gas lens for most everything. I run 12-15 scfh. I ball the tip of new tungsten on piece of scrap for few seconds and full power for the weld, so if I have the max amps at 150 for the weld that's what I ball it at in AC mode. If I don't and I go right into a fillet weld I get multiple balls that make the arc unpredictable.

Reply:I get the multiple balls if I don't ball it up in advance also. For 1/4" Al and significant mass (20 lb. structure) this forum advised me to lower freq. from 150 to 80Hz and use 1/8" W vs 3/32. It worked well (+preheat before starting).

Reply:When I still owned a syncrowave 250, I would use a stubby gas lens and a #7 cup on my #20 water cooled torch with 20 CFH of gas for virtually everything, including aluminum. I like the ergonomics of the gas lens better. Anything over say 150 amps, especially quarter inch aluminum I would size up to a 1/8 inch diameter tungsten. I never balled my tungsten I only shaped it like a crayola crayon with a truncated tip. I never had too much issue with balling with that size tungsten. I also only used 2% lanthanated (blue) tungsten for everything. These aren't best practices by any means, just want worked for me. I think the answer for you is experiment and see what works and what you like and don't worry about absolute rules or best practices. If it works, use it.Miller Multimatic 255

Reply:Like Louie I use a #7 cup with a 3/32" tungsten. When I weld thicker alum or steel I move up to a 1/8" cup and #8 cup. The reason is want the coverage without choking the gas flow from a fat tungsten. My shop formula that works up to a #12 cup is 2 times to 3 times the cup size. So for instance a #12 cup would be between 24cfh minimum to 36cfh maximum with 30cfh being the mean. I set to the mean and go up or down from there depending on whether I am welding inside or outside corners. Inside corners trap the gas for benefit.These days I only use gas lens unless I need an extended cup for reach. Extended cups tend to calm the turbulence anyway. And 2% thoriated for steel, 2% lanthanated for alum. I point the thoriated on both ends and lanthanated on one end only for identification. But chart your own findings after experimenting. Do what works for you.Weld like a "WELDOR", not a wel-"DERR"

MillerDynasty700DX,Dynasty350DX4ea,Dynasty200DX,Li ncolnSW200-2ea.,MillerMatic350P,MillerMatic200w/spoolgun,MKCobraMig260,Lincoln SP-170T,PlasmaCam/Hypertherm1250,HFProTig2ea,MigMax1ea.

Reply:I like a frequency of 80hz on my Lorch 200 for 1/8" in general. 120hz+ for outside edge welds.40-50hz for 1/4" although it's on the limit for my amperage.Balance stays around 25% EP for clean new alloy. 30-40% for old cast stuff. I use a 3/32" 2%lanth or E3 for everything... gets semi sharpened and then the end blunted off. The Lorch set pre-balls the tip with a burst of EP at arc-up which works really nice.Murphy's Golden Rule: Whoever has the gold, makes the rules.

Reply:

Originally Posted by Munkul

I like a frequency of 80hz on my Lorch 200 for 1/8" in general. 120hz+ for outside edge welds.40-50hz for 1/4" although it's on the limit for my amperage.Balance stays around 25% EP for clean new alloy. 30-40% for old cast stuff. I use a 3/32" 2%lanth or E3 for everything... gets semi sharpened and then the end blunted off. The Lorch set pre-balls the tip with a burst of EP at arc-up which works really nice.

Reply:Could be just me, but I have much better results with a #5 cup. I was very determined to use a #8 gas lens for everything, but it never gave me good results on aluminum.Anything over 180a I found 1/8 tungsten works better280a and up I switch to a #6Sync 250

Reply:Great stuff, thank you. I just finished an aluminum intake tube for a friends Corvette project. It needed a mounting tab and a small PCV tube. Tab was 3/16, 4" tube wall was 1/16. I used 160 amp setting, 65 EN, 3/32 (light green), 150HZ #5 cup stubby. Balled the end with 30 EN. Results were good, the problem was not the setup but my inexperience with welding a small diameter PCV fitting (3/8" OD) to a 4" OD tube for an LS7. It came out good (leak tight, solid) but not as nice as I would have liked.I have used most of the settings provided in this thread. I also go with 1/8 Tungsten for thicker material and a #7 or #8 cup (lens or no lens), I like 2% La for just about everything (above example excluded). My welder is an HTP 221 so I have limited current and like to preheat thicker sections. At this point, it's not the setup but my limited experience. I am my worst critic...

Reply:

Originally Posted by 2strokeforever

Could be just me, but I have much better results with a #5 cup. I was very determined to use a #8 gas lens for everything, but it never gave me good results on aluminum.Anything over 180a I found 1/8 tungsten works better280a and up I switch to a #6Sync 250

Reply:Yes, seems to work fine

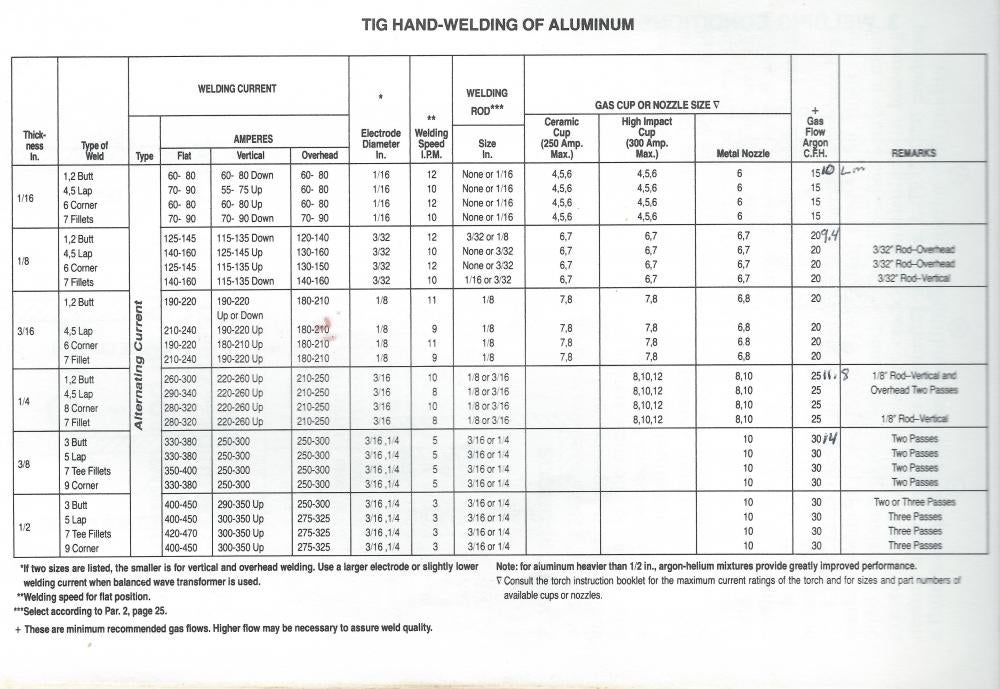

Reply:Here's a welding guide from an Ltec handbook, circa 1990. All of the other literature I have, Panasonic, Daihen, and other modern guides have similar settings. "Don't use a gas lens" centers around the "pop" you're going to get if you touch the tungsten to anything molten aluminum. Many times it will ruin the gas lens, or require removing one or two screen layers. But there will always be aluminum contamination, and you'll never want to use that lens on anything you don't want to get aluminum in. Use it if you want, but there's no real tangible advantage like you would see with stainless, titanium, etc. Argon envelope determines cleaning area. So while you never need one of those silly 12 or 16 cups, an 8 gives you a wide cleaning area, and a 5 can make for a "white zone" you can hardly see. But if you use a 5 on an edge for build up, or an outside corner, for instance, you may see it form "gray skin" oxidation while welding, as the envelope isn't giving adequate coverage. Gas flow is cup dependent. For a 5 cup, I'm going to use 5L/M (10cfh). Running it up to 10L/M (20cfh) is going to cause a lot of turbulence with a #5, and make it worse. Running a #8 cup, it's going to want around 8-10L/M (16-20cfh). Freq? Depends on what you're doing. Inside corner on something like 1.6mm or thinner sheet, I'll run 400Hz, as it keeps a tight, focused arc with less chance of blow through. Thick sections, maybe down to 60Hz. General automotive fab for 1/8" wall sheet, like an intake manifold 120-200Hz. People love to argue all day about what tungsten is best... I run red 2%T on everything because it works on everything, and I have enough of it to last a lifetime. It all works, and it's hilarious to sit back and watch hobbyists argue over the merits of one over another. I worked aerospace for the USAF as a contractor for 20 years up until about 10 years ago. AL 6061, 4130, Co L604, In 718, 321 SS, 440A SS, 6AL4V Ti, and mag...all welded with 2% thoriated, and a #8 gas lens.

Last edited by JDM Welder; 04-01-2022 at 06:38 AM. |

|