|

|

Finally decided to join the forum after lurking for a while. Time to give back for the great info I got.I have a Lincoln SP170T 220v mig that has served me well as a hobby welder. From time to time I have to do some small aluminum repairs. I hate having to change out the liner just to do a couple inches of welding.Lincoln makes a nice spool gun for their SP Series migs. I wanted one, but local welding supply says you can't have it. More correctly they said it won’t work with your machine. We can sell you this new SP-180 for …………Did some research and some internet reading on DIY conversions. My goal was to have a functional spool gun that is easily switchable and doesn’t look like a clown put it together. Not real pleased with the looks of some of the YouTube conversions.Decided modify my SP-170 to accept a spool gun. Seeing this was an experiment I opted for a Coplay Norstar SL-100 spool gun off eBay for under $100. Turns out the seller is one of the brick and mortar welding supply companies in the region. Was advised to order their switch kit also, which added another $16.00. Not needed don’t waste your money.

s-l1600 by wcstory, on FlickrGot kit in mail a couple days later. Let the Frankenstein Works begin in the shop.I test fit the spool gun welder end into the socket for my mig gun, it fit as expected. Now for the controls. Going in I knew the Lincoln OEM replacement connectors were way too expensive. I couldn’t find a generic exact match so I opted to order a similar 4 pin connectors off Amazon. They are GX16-4 Aircraft Panel Connectors

index by wcstory, on FlickrI cut off the control connector leaving enough wire to be able to splice it back if my project failed. That decision cost me extra work. If you do this, cut it off right at the connector. I had to extend the leads by 6"

IMG_20170211_160633862 by wcstory, on FlickrFrom a YouTube video I knew what control wire I needed to access. The trigger/gas solenoid wires and the wire feed motor wires. Off comes the cover.

Screenshot 2017-02-12 08.46 by wcstory, on FlickrFind the Grey and Black wires going from the control board to the wire feed motor. Refer to wiring diagram on cover. I cut them up high near the front of the case. I want to be able to switch power to the drive motor from Spool to MIG so I’m not running both.

IMG_20170212_135259426 by wcstory, on FlickrI drilled a hole in the front of the case for the MIG/Spool switch. Watch out for the black tube that is your gas feed. I ended up using the Double Throw Double Pole switch from the useless wiring kit I bought. That was an expensive switch. I extended the Hot and Return wires from the control board go to the middle two lugs on the switch. From the top two lugs I connected the Hot and Return feed to the MIG drive motor.

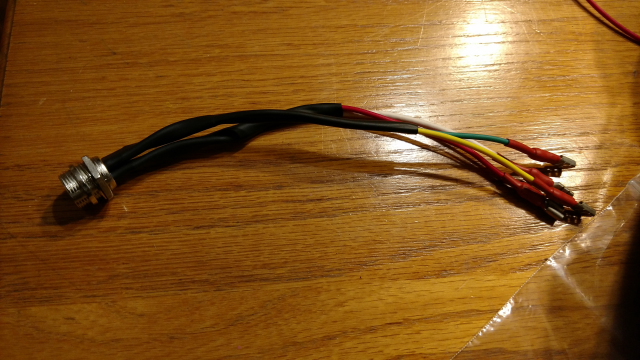

IMG_20170211_154942961 by wcstory, on FlickrOut came the multimeter and I determined the Red & White is the drive motor and the Yellow & Green are the Gas Solenoid/trigger. To be sure I opened the spool gun and checked the wire colors. In the picture you can see the test wires I ran to the spool gun trigger and drive feed. It worked!

IMG_20170215_203939881 by wcstory, on FlickrNow to make it a quick connect and look professional. I drilled another hole for the 4 pin bulkhead and got out the soldering set, wire and heat shrink tube. I decided to assign pins 1&2 for the Trigger and 3&4 for the Drive Motor.

IMG_20170215_210015697 by wcstory, on FlickrNext I cut the Trigger leads off my stock MIG gun and soldered on a Female 4 pin connector

IMG_20170215_211715752 by wcstory, on FlickrNow I have a spool gun for aluminum. The Norstar is not the same quality as the Lincoln, but it works. I played with some scrap aluminum then took the opportunity to do some repairs to a Little Giant ladder for a contractor friend. The results are decent. I expect better results with practice

IMG_20170215_212116309 by wcstory, on FlickrCostsCoplay Norstar SL-100 95.00DPDT Switch 16.00 (should cost 6.00)GX-16 -4 Aviation connectors 8.00Wire and heat shrink tube 11.00Total 130.00I’d guess I had 6-8 hours into the project over 3 evenings after work. I made some mistakes soldering and had to redo the male socket on the machine side twice. It would take 3 hours if I had a set of instructions so I wrote this guide.Last edited by wcstory; 02-16-2017 at 06:44 PM.

Reply:Nice job.

Reply:This is what i did.......http://weldingweb.com/vbb/showthread.php...n+on+the+cheap

Reply:So on the old mig gun there is 2 wires what pins did you connect to on the female end? On the Spool gun you solder all 4 wires respective? The 2 motor wires on the 4pin plug go up to the toggle switch correct? Thanks for the help in advance.

Reply:Toggle switch is used to switch motor power from welder to spoolgun. And on some units to turn the gas valve off, if the gas is connected to the spool gun and the spool gun has a built is gas valve.Some of the new spool guns connect to the drive and pull power and gas from there. then the switch only switches the motors.Trigger wires should not need to be changed. In this case he moved the gun trigger wires to a plug on the welder front from a plug on the panel above the mig wire drive. so the new plug will work with both the miggun and the spool gun.Just like the new small welders do.

Reply:Wcstory, are you still around? New member here for my eyes on a 170t wanted to talk to you about this mod please. Thanks, Josh |

|